Definition of the Distilling Ball. What Is It and What Is It For ? Its Meaning

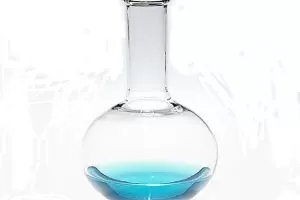

The distillation balloon, also known as a fractionated distillation flask or fractionating flask, is a vessel with a round bottom and a long neck from which a side arm protrudes. It is mainly used for distillation, the process of separating a mixture of liquids with different boiling points by evaporation and condensation. The liquids with lower boiling points are first vaporized and then rise through the neck and into the side arm, where they condense again and accumulate in a separate vessel.

In this way, the distillation ball has a purpose similar to that of the retort. However, it offers certain advantages over the retort, because its vertical neck facilitates the addition of liquids. The neck also allows inserting a thermometer, if desired, to record boiling temperatures. The positioning of the side arm along the neck varies according to the characteristics of the solution to be distilled.

The higher the boiling point of a substance, the lower the side arm should be above the neck, which gives the vapours a shorter distance to rise and less chance of recondensation before reaching the side arm. When working with chemicals in the laboratory, it is sometimes necessary to separate mixtures of different liquids.

Because many chemical mixtures are volatile and can be harmful to humans on contact, one of the most widely used methods is distillation, which is achieved by using a distillation balloon or flask. Distillation is a common operation in many laboratories for the purpose of separating and/or purifying components of a liquid mixture.

The apparatus used consists of three main parts: a distillation balloon (or distillation flask) to heat the mixture and volatilize the components, a condenser to cool the vapors back to the liquid state, and a collection vessel. The apparatus is generally made of glass and is therefore subject to breakage. All the components of the distilling apparatus must be secured to a stable support or frame to prevent it from falling down.

All glassware, in particular the part to be heated, should be checked for cracks before use. The connections between the glass parts may involve rubber or cork stoppers, but in more modern appliances standard conical connections are used. If stoppers are used, it must be known that hot vapors will not react with the rubber or cork and thus contaminate the products. If standard conical connections are used, any lubricant used to make airtight seals should also not react, melt or evaporate and contaminate the product.

Function and Use of the Distillation Equipment Ball

The distillation ball is a special glass or plastic container that has an outlet near the top and one near the bottom to separate the layers of two immiscible distillates (such as oil and water in steam distillation of essential oils).

Distillation is an excellent purification tool for many liquids and may be used to purify products from a chemical reaction. Distillation can also be used to purify reagents that have degraded over time. This is why the distillation ball is so important.

Functioning of the Distillation Ball

The ball or distillation flask is a round bottomed flask. The liquid to be distilled must fill the distillation at 50-60% of its capacity. To promote an even heating of the liquid. A magnetic stirring bar is added before applying heat to the distilling flask.

Irregular chips provide sites for vapour bubbles to form, or alternatively the liquid is agitated with the stirring magnet while heating. Never add a boiling chip or stirring bar to a hot liquid! Doing so can cause a seemingly calm liquid to boil suddenly and violently.

The Distillation Adapter

The adapter connects the distillation flask, the condenser and the thermometer. This type of adapter is often referred to as a distillation head. The frosted glass seals must be aligned and connected tightly to prevent leakage of the vaporized liquid.

Leaks will cause some of the liquid to be lost and will contaminate the laboratory environment. The position of the thermometer is adjusted so that the bulb is approximately level with the side arm of the adapter connected to the condenser. Vapours from the heated liquid must completely surround and touch the thermometer bulb to obtain temperature data from the thermometer during distillation.

The Condenser

The condenser cools the steam by causing it to liquefy (condense) and directs this condensate to the receiving flask. The water supply is connected to the condenser with rubber hoses. Water flows to the lower hose connection (furthest from the distillation ball) and out of the upper hose connection (i.e. “in at the bottom, out at the top”).

Before opening the water flow, check and connect the hoses carefully to ensure that they are secure and will not come loose. A margin of safety can be obtained by twisting the cable around the hose connections. The water flow is adjusted so that there is a constant flow of cold water to the condenser. The receiving flask

The container for collecting the liquefied vapour is called the receiving flask. It can be a round-bottomed flask, an Erlenmeyer flask, a bottle or a graduated cylinder. The receiver is connected to the condenser via an adapter. A key feature is that the system is open to the environment – never heat a totally closed system!

How it happens:

- Heat is slowly applied to the distillation flask. The amount of heat to be applied is determined by a distillation rate. The liquid should bubble and vaporize gently. As the vapour leaves the liquid, the temperature of the apparatus rises.

- The vapour will fill the distillation ball and most of the distillation head, the thermometer bulb should be completely surrounded by the vapour. If the vapour is drawn off beyond the thermometer bulb without contacting it, the boiling point measured will be low.

- The vapour condenses and drips into the receiving flask through the condenser tube. Typically, the liquid should drip into the receiving flask at a rate of approximately 15-20 drops per minute. If the distillation rate is too fast, the distillation ball must be removed from the sand bath.

- With rapid speed, it is likely that the boiling point measured will be inaccurate and the purity of the distilled liquid will decrease. If the liquid being collected has a low boiling point (<40°C), the receiving flask should be cooled in an ice water bath.

- The boiling point behaviour measured during the course of a single distillation is represented as the liquid evaporates and the vapour comes into contact with the thermometer bulb, the temperature rises.

- The temperature stabilizes at the boiling point and most of the liquid. It distills on the receiving flask. The temperature drops when almost all of the liquid is distilled (but never boil a liquid dry!). Boiling point of a pure substance depending on the amount of liquid distilled.

- When the temperature begins to drop, distillation is stopped by removing the distillation flask from the sand bath. Note that the boiling point of the collected material is actually a range rather than a single point.

Uses of the Distillation Equipment Ball

The distillation ball has different uses, although its main function is to separate substances by heating them and taking their content from a liquid to a gaseous state, and thus being able to separate the elements according to the boiling points of each substance, to then pass to a condenser and a receiver.

In biology laboratories it is used for the preparation of culture media. It is widely used when working with mixtures of substances with violent chemical reactions. It is used in cases where substances must be heated to high temperatures; for low temperatures the Erlenmeyer flask is used.

It is also used to replace the beaker when dealing with a substance in a liquid state that must be constantly stirred. Thanks to its shape, the distillation ball avoids loss of its content. By spilling and by evaporation.

History and Origin of the Distilling Ball. Who Created It ?

As far as we know, the process of distillation was invented by Egyptian alchemists, who used a large number of devices designed to vaporize volatile substances and treat metals with them. It seems that, occasionally, a kind of liquid distillation was performed. For example, seawater was heated in covered cauldrons and the condensed drops were shaken off the lids, in order to use them as drinking water.

Likewise, fish oil was made by heating the tar and subsequently condensing its vapour. Mercury was obtained by heating cinnabar (mercury sulfide ore) on an iron plate, placed inside a pot covered with a pot or ”ambix”, in which the mercury vapor was condensed.

Later, this term was used to designate the complete apparatus of distillation, in Arabic al anbiq, from where our still comes. The Greek alchemists, in the first century of our era, invented the alembic to distill substances. An alembic or distiller is composed of three parts: a vessel in which the material is heated to be distilled, a cold part to condense the steam produced and a container to collect it.

The distillation was invented as a means to obtain a liquid capable of attacking or coloring metals. In the middle of the 19th century, a way of making transparent, ductile glass that can withstand continuous heating and cooling was discovered. This glass had its immediate application in the manufacture of laboratory equipment and material. This meant an enormous advantage over the metal and ceramic equipment that were being used, especially because of the chemical resistance of the glass, its transparency and its malleability, which allowed the manufacture of new and complicated laboratory instruments.

In the field of distillation, the stills were modified and flasks, columns and condensers appeared, similar to those used today. Since then, distillation has been one of the most widely used separation techniques in laboratories and chemical research, while also being used as an analytical technique. “The appropriate glasses… for distilling in a bain-marie, and with fires of ash, sand, filings and dung, a glass gourd or cucurbita with its pointed capital, and its container which is a long-necked flask, is necessary. To distill per medium cornutum, two flasks are needed, or a flask and a large container called a ball. The flask was created by the chemist Emil Erlenmeyer in 1861 and therefore there is a type of flask that bears his name.

After that, other instruments began to emerge that maintained the same concept and are considered flasks, such as the distillation ball in this case. However, in the first centuries of our era, there were already alchemists who created instruments similar to what is known today as a flask. There is no exact reference to the inventor of the distillation ball.

Liquid Level in the Distillation Ball

- At the beginning of the distillation, the distillation vessel should be between half full and two thirds full. If the pot is too full, the surface area is too small for rapid evaporation and the distillation proceeds very slowly.

- If the pot is not full enough, there will be a large retention volume and loss of sample. The retention volume is the amount of vapour in the flask and head along with the liquid required to wet the internal walls of the apparatus.

- A typical retention volume is one or two milliliters, which can lead to significant product loss, especially in a small-scale experiment. If you fill a flask and find it too full or not full enough, choose another flask size from your laboratory drawer.

Characteristics of the Distillation Ball

- The distillation ball has three main components: the spherical base, a cylindrical neck and a cylindrical side arm. As the neck is narrow, it can be covered with a frosted stopper or with hydrophobic cotton.

- The upper part of the neck of the distillation ball is usually sealed with a cork or rubber stopper. As the heated gases change to a gaseous form, they rise through the cylindrical side arm which is connected to the neck of the flask.

- Because extreme heat is used in the distillation process, it is important that the distillation flasks are made of resistant glass (usually borosilicate, pyrex or quartz glass) that can withstand high temperatures and with a thickness according to its uses.

Considerations:

- Simple distillation procedures are used to separate liquids that have a difference in boiling points of at least 50 degrees Fahrenheit. Liquids with the lowest boiling points will produce the richest vapors when heated. It is important to heat the distillation ball slowly while constantly checking the temperature to separate the different liquids more effectively.

- The distillation ball should preferably be round bottomed rather than flat bottomed to soften the boiling. The balloon should never be filled more than halfway with the liquid mixture to be distilled. Further filling causes bubbles and sometimes foam to contract in the narrow part of the ball and get out of control.

Warnings

Never allow the flask to distill liquids until dry. Residues of the mixture may contain flammable peroxides, and the change of these peroxides that ignite after distilling the liquids increases when the ball is allowed to overheat. It is also important to ensure that the ball’s connecting joints are properly secured so that no vapors can escape. If vapours escape from the connection points, there is a possibility of fire or explosion when the vapours come into contact with the heat source.

The heating of the distillation flask requires care. The liquids being distilled are often flammable so flame is not the preferred heat source. Heating mats or sand baths are good sources of heat to suit round bottom flasks. Care should be taken not to let the vapors near the control of the switches that may be caused by opening and closing. Doing distillation inside a hood is a good practice.

A final word of caution about the appliance is in order. There have been cases where operators have decided to make the connection between the condenser and the receiving vessel a tight one by means of a standard taper or plug connection. This should not be done, as it creates a completely sealed system. When the distillation flask is heated and the vapors begin to rise they will expand and create a pressure in such a sealed system that they will inevitably blow out the separation joints.

In general, this causes the vapors to escape into the (hood or lucky) surrounding room if the glass material is not broken. Always allow a pressure relief opening in the distillation system between the condenser and the receiver vessel.

Distillation Ball Capacity

The capacities of the distillation ball may vary in size and composition. They can be found in different sizes according to the needs of the analysis, that is, with a capacity of 100 ml, 125 ml, 250 ml, 500 ml and 1000 ml.

Price in Euros and Dollars of the Distillation Ball

- 250 ml Lab distilling flask, distillation flask, with side arm. Price: 11,40 Euros or its equivalent in $

- QCY AT Glass Flask 500 ml 24/40 Laboratory Glass Distillation Kit Ware. Price: 105,62 Euros or its equivalent in $

- ZhengFei Module Laboratory glassware Kit of Short Neck Flat Bottomed Distilling Flask 100/150/250 ml (size: 150ml). Price: 28.58 Euros or its equivalent in $

Related Products in ALPHAPEDIA

SCALPEL PRICE: Reviews and Offers

USE OF VOLUMETRIC FLASK

PRECAUTIONS WHEN USING A BEAKER ?

PROPIPETTE PRICE: Prices, Reviews and Offers

SCALPEL DEFINITION

CAMRY SCALE: Prices and Reviews on Amazon

Other Products of Interest in ALPHAPEDIA

MINILAND SCALE: Prices and Offers

CHEAP AND BEST MOBILES

CABLE REEL IMAGE

DOG AND CAT SCALES: Prices and Offers

FLOORING AND TILES NEAR YOU AND ME

SCREW: Definition, Examples, Types and Sizes For Wood

DISTILLATION EQUIPMENT IMAGE